- Home

- Juice Bar Equipment

- Citrus Juicers

- Citrus Juicer Accessories

- Vegetable & Specialty Juicers

- Cold Presses

- Blendtec Blenders

- Frozen Treat Machines

- Cold Drink Dispensers

- Granita & Slush Machines

- FS-Apiqe Water System

- Zummo ZV25 OJ Vending

- Mobile Juice Bar Kiosks

- Automatic Cup Sealer

- Zummo Isla Automatic Self- Service Pineapple Corer

- Kitchen

- Refrigeration

- Refurbished

- Bottles & Labels

- Photos

Commercial Egg Separators

If your kitchen or facility runs through thousands of eggs a day, manually separating yolks and whites is not just a pain, it’s a bottleneck. You’re wasting time, burning labor, and risking inconsistent results.

That’s where the RX Series from OVO-TECH steps in. These machines are built for businesses that need real output, not kitchen hacks.

Whether you’re processing 3,000 eggs an hour with the RX-0 or stepping up to the RX-6 with a 39,000 eggs per hour capacity, you’re getting serious power in a clean, compact design.

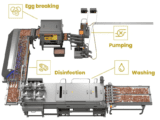

Here’s how it works: the machine mimics human hands using precision-engineered knives to break the eggs.

Each egg is routed through a buffer system and quality controller that filters out any damaged product. From there, the whites and yolks are separated cleanly, ready for use, no mess, no manual labor. Even better? The machine is self-cleaning.

Built from surgical-grade stainless steel and backed by a 1-year warranty, these machines are made to last in tough commercial settings.

OVO-TECH has earned a reputation across Europe for cutting-edge, high-output egg processing equipment. Their lineup also includes washers, disinfectors, steamers, and other time-saving gear to streamline every part of your egg workflow.

At Freshly Squeezed, we’re proud to be OVO-TECH’s trusted U.S. distributor.

We offer on-site demos, expert support, and flexible financing so you can upgrade without the upfront sting. Leasing and rental plans are available to fit any budget.

The versatility of OVO-TECH’s lineup extends beyond just the egg yolk separator. Their portfolio also consists of egg crackers, egg washers, egg disinfectors, as well as egg and food steamers, providing comprehensive solutions for all aspects of egg processing.

Ready to level up your operation with commercial-grade egg processing equipment? Call us at (800) 997-5352 to schedule a demo or get a custom quote. We’ll help you find the right machine for your volume, space, and workflow.

RX-0 Egg Breaker

This OVO-TECH egg breaker utilizes special pneumatic suction cups to replicate the action of human hands, coupled with a specially designed knife for breaking eggs. After undergoing a quality control check, the eggs are processed through a separator that efficiently divides yolks from whites. This method, noted for its hygiene, is a unique innovation by OVO-TECH.

The RX-0 egg breaker model offers versatility with two modes of operation: fast and slow. It also includes a built-in feature for cleaning its pneumatic system.

The machine is designed to automatically retrieve eggs from the feeder tray. It offers two operational choices:

1. Egg breaking with separation, where it directs egg whites and yolks into separate containers.

2. Egg breaking without separation, channeling both whites and yolks into the same container.

Output: 3000 eggs/hour – replaces 3 people

RZ-1 One Row Egg Breaker

The RZ-1 egg breaker is designed to crack eggs and offers the added capability of separating yolks from whites, depending on the selected operating mode.

This machine features adjustable speed control, allowing the operator to modify the operational pace as needed.

Additionally, the height and impact force of the knives can be adjusted, which is particularly useful for handling eggs with fragile shells.

Output: 3200 eggs/hour – replaces 7 people

RX-1 Egg Breaker

The RX-1 egg breaker features a gravity-fed, self-regulating feeder and specialized rollers for smoothly guiding eggs into the breaking section. Its high efficiency is attributed to top-tier, innovative breaking mechanisms.

The machine cracks eggs using specially designed knives that mimic the precision of human hands, a method renowned for its hygiene. Following this, eggs pass through a quality control tray and then proceed down a separator ramp, where yolks and whites are divided.

Additionally, the machine includes a universal eggshell crusher, remarkably reducing the volume of eggshells by 95%. After use, cleaning is made simple with the integrated CIP (Clean-In-Place) system. The entire machine is constructed from stainless steel, ensuring durability and longevity.

Output: 6500 eggs/hour – replaces 14 people

RX-2 Egg Breaker

The RX-2 egg breaker from OVO-TECH utilizes a gravity-assisted, self-regulating feeder and custom-designed rollers to transport eggs into its breaking section. Its outstanding performance stems from the use of superior, cutting-edge breaking mechanisms.

The machine cracks eggs using specially designed knives that replicate the action of human hands, a process known for its exceptional hygiene. Following this, eggs are inspected on a quality control tray before being routed down a separator ramp for yolk and white separation.

Additionally, the machine features a universal eggshell crusher, significantly reducing eggshell volume by 95%. For easy maintenance, the machine is equipped with a built-in CIP (Clean-In-Place) system for post-operation cleaning.

Output: 13,000 eggs/hour – replaces 28 people

RX-4 Egg Breaker

The RX-4 features an efficient gravitational, self-pacing feeder and rollers specifically designed for smoothly transporting eggs to the breaking area.

This machine delivers exceptional performance, thanks to its state-of-the-art, innovative breaking mechanisms. It cracks eggs with specially designed knives that closely mimic the delicacy of human hands, making it a highly hygienic method for whole egg breaking.

After cracking, eggs pass through a quality control tray, then move down a separator ramp where the yolks are neatly separated from the whites. The machine also boasts a universal eggshell crusher, adept at reducing the volume of eggshells by an impressive 95%. For convenient cleaning post-operation, the machine is equipped with an integrated CIP (Clean-In-Place) system.

Output: 26,000 eggs/hour – replaces 56 people

RX-6 Egg Breaker

The RX-6 is the largest model and it incorporates a gravity-based, self-regulating feeder along with specially crafted rollers to guide eggs into the breaking area. Its top-tier performance is attributed to advanced, innovative breaking mechanisms.

The machine utilizes specially designed knives for breaking eggshells, skillfully replicating human hand movements, a feature celebrated for its hygiene. Once cracked, the eggs are checked on a quality control tray, followed by a separation process on a ramp where yolks are isolated from whites.

A notable addition is the universal eggshell crusher, which efficiently reduces the volume of eggshells by 95%. Post-use, cleaning is streamlined with the machine’s built-in CIP (Clean-In-Place) system. The entire structure is made from stainless steel, ensuring durability and longevity in its operations.

Output: 39,000 eggs/hour – replaces 85 people

For more information or to discuss how we can meet your egg processing needs, give us a call at (800) 997-5352

Related: Commercial Egg Washing Machines

Related: Centrifugal Egg Breakers

Related: Complete Egg Processing Lines