Dull Nutrifaster Blades Are Costing You Yields

by Polina

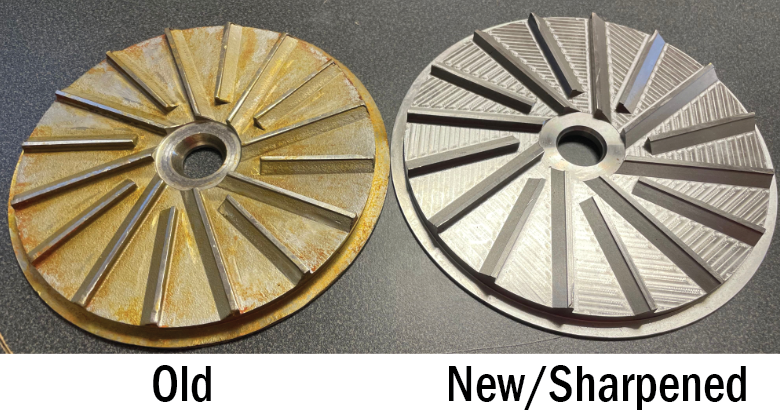

Sharp blades are the quiet edge that make the Nutrifaster N450 feel like a brand new machine. When the cutter plate is crisp, it slices clean through cell walls instead of grinding them to mush. That single difference shows up in everything that matters.

You get more juice from the same produce. Sharp edges release liquid fast and clean, so less ends up trapped in the pulp. Wet pulp is money in the trash, and you can see it at a glance.

Flavor improves too. Clean cuts mean fewer shredded fibers and less heat, which keeps sugars bright and acids balanced. Customers taste that as fresher, sweeter juice with a smoother finish.

Clarity gets better the moment you sharpen. Torn produce leaks pectin that clouds bottles and builds extra foam. A sharp plate keeps the stream clear so your bottles look as good as they taste.

Speed is an instant win. The N450 moves through apples, carrots, and greens with less resistance, so your line keeps flowing when the morning rush hits. That keeps staff happier and your tickets moving.

A sharp plate is lighter work for the motor. When the edge is dull the machine has to muscle through every piece, which adds heat and strain. Lower strain means fewer surprises and a longer service life.

Consistency also levels up. With a fresh edge your recipes hit the same yield and texture day after day, which makes batching simple and predictable. If you care about cost of goods, you care about that.

Now for the pain point most owners feel even if they do not say it out loud. Dull blades creep up slowly, so you adapt without noticing. Then one day you are buying an extra case of carrots to hit the same numbers and wondering why the machine sounds tired.

The solution is simple. Treat the cutter plate like a wear part with a real schedule. Inspect it, sharpen it on a regular cadence, and rotate a spare so you are never down.

What does regular look like. For busy shops, plan on professional sharpening every few months and earlier if you run a lot of hard produce. Lower volume shops can stretch it, but not by much, since oxidized micro nicks still drag yield and clarity.

Daily care matters more than most people think. Rinse immediately after service, then wash and dry thoroughly so sugars do not harden on the edge. Avoid harsh abrasives that round the profile, since rounded edges act dull even when they look shiny.

Watch for the telltales of a plate that needs attention. Pulp coming out wetter than usual, bottles foaming more, or the machine sounding louder under load are all early warnings. If your yield notes show a slow slide, that is the edge talking.

Sharp blades also make training easier. New staff get better results with less coaching when the machine is doing the real cutting. That reduces mistakes and saves produce, which frankly is the easiest money you will ever make.

One more thing that operators love. A sharp plate keeps greens from smearing into a fibrous paste, which means less clogging and faster rinses between recipes. Cleanup feels lighter because it actually is.

If you want a simple plan, keep two cutter plates. Run one, send one for sharpening, and swap on a set day so you never press your luck. Log yield by recipe so you can spot drift before customers do.

Here is the takeaway. Sharp blades give you higher yield, better flavor, clearer juice, faster throughput, lower strain on your N450, and happier staff. All it asks in return is a little routine and a spare plate on the shelf.

Check your plate today. If pulp is wetter, flavor feels flat, or the rush is dragging longer than it used to, that edge is ready. Sharpen it, swap it, and watch your numbers jump right back where they should be.

Contact us to learn more at in**@******************ed.com