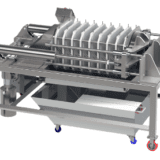

Goodnature X-6 Cold Juicing Press

X-6 — Six Layer System |

| The X-6 provides processors with a completely self-contained pressing system, capable of outputs of 40-60 gallons per hour. The commercial duty electric-hydraulic unit requires only one operator and is compact in size– finding ideal applications in small to medium size juice and herbal facilities, as well as pilot plant or laboratory settings. |

| Operation is simple: Raw material is fed manually or by conveyor into the EG260 Grinder. The powerful grinder produces a fine slurry which is ground onto a stainless steel tray. For some applications, the grinder and stainless steel tray are not needed. The pomace is then manually directed into the filter bags with a plastic spatula. With a push on a lever, a moving platen compresses the racks together, squeezing out liquid. At the end of the pressing cycle, the operator pulls back on the lever to reopen the pressing module. The catch pan is drained and removed. A bin is put in place beneath the pressing area and the module is then rotated 180 degrees upon its center axis to release the dried cakes. The pressing module is then returned to “ready” position for the next cycle. |

| Ease of Sanitation: Because sanitation can make or break an operation, the X-6 allows for total and efficient clean-up. With no belts to trap mash, the entire press area can be disassembled in less than 1 minute for spraying and/or soaking. All contact parts are constructed of sanitary stainless steel or HDPE plastic. Portability: To facilitate cleaning of the machine, the entire grinder and press area can be removed. Locking castors ensure stationary operation. |

| Ergonomic: With all elements of the grinding and extraction process within easy reach of a single operator, the X-6 is easy and economical to use. In addition, it makes the same quality juice and extracts as a traditional hydraulic rack and cloth press, with no bending or lifting of racks, and no time consuming assembly of cloth layers required. |

| Rugged Construction: Using the same construction principles as our presses that produce 1000’s of gallons per hour, the X-6 is built to last. With racks of 1/2” HDPE plastic and heavy duty Frame construction, replacing racks will be a thing of the past. |

| High Pressure: Just as the X-6’s construction is based on that of presses 10x its capacity, so also is the hydraulic muscle. The pressure on the pomace cake can exceed 100 PSI with every squeeze. |

| All-In-One: For small and medium size facilities, the X-6 offers a complete system solution. Whether for the beginner or someone moving up to a higher production capacity, the X-6 is the entire “plant” in one package. |

| Capacity: 480 lbs (217 kg) per hourOutput: 40-60 US gallons (151- 227 liters) per hourPower Requirements: Hydraulic unit– 1 HP, 115/230 volt, 15/7.5 amps, 60 HZ, single phase

Grinder– Available in the following: 1 HP, 110/220V, single phase, 1725 RPM 2 HP, 110/220V, single phase, 3450 RPM 2 HP, 220V with variable speed Weight of Press, Crated: 1245 lbs (565 kg) Weight of Press and Grinder, Crated: 1364 lbs (619 kg) Pressing Unit Dimensions: 51 x 46 x 46 in. high with castors (130 x 117 x 117 cm high) Grinder; Mounted on the side of the press, 55 in. high (140 cm) Removable Racks: HDPE 23 x 23 in. (59 x 59) Finish: Epoxy powder coated for excellent corrosion and wear resistance. Freshly Squeezed is not in any way affiliated with, or endorsed by Goodnature Products, Inc. whose products may, from time to time, be available through us. Any Goodnature products available through us have been reconditioned and/or refurbished by Freshly Squeezed, not by Goodnature Products Inc. Any warranty provided is covered by FreshlySqueezed and not by Goodnature Products, Inc. |